iron and steel

Amatrol's Iron and Steel Program combines technician training courses with world-class simulators featuring industry-standard components so that learners are prepared for successful iron and steel careers at foundries and related plants.

Amatrol offers unrivaled pairing of depth and breadth and hands-on skills in areas such as electrical, power, mechanical, electronics, and many more...

Amatrol's online iron and steel courses build job-ready competencies through theory and hands-on applications.

Amatrol's peerless multimedia curriculum utilizes text with voiceovers, pictures, videos, stunning 3D animations, and interactive quizzes and reviews that engage learners in knowledge and concepts to provide mining courses online.

Through partnerships with key industry leaders and leading educators, Amatrol developed the right balance of knowledge to train learners to work in their chosen field...

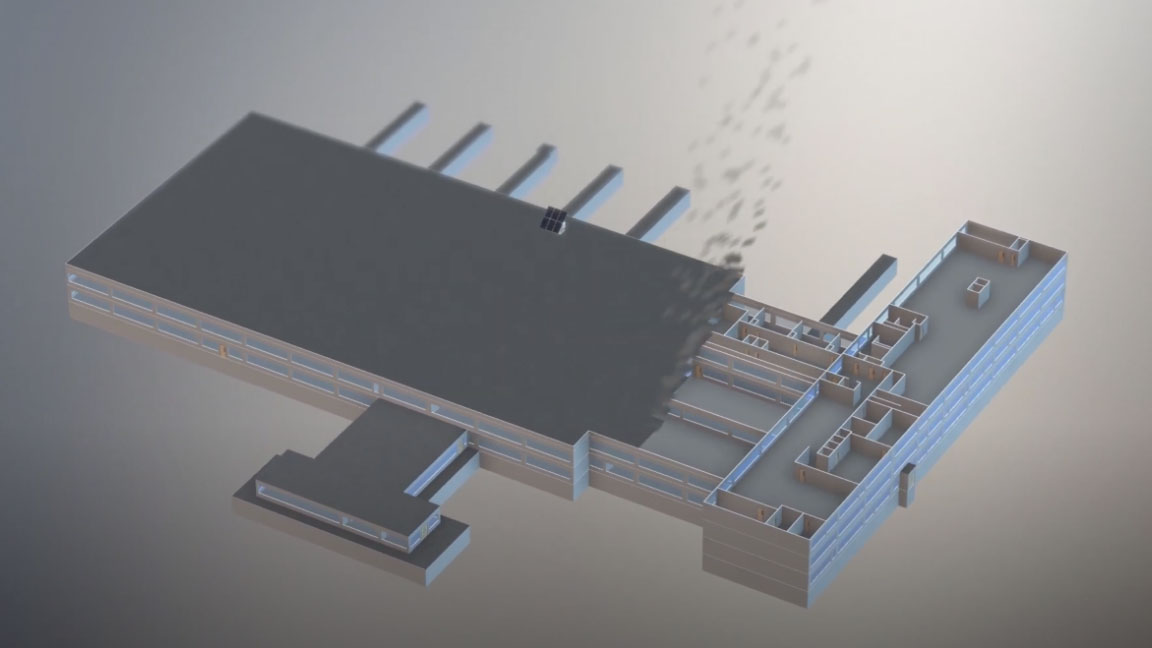

Amatrol's virtual simulators replicate hands-on equipment with realism and skill-building, mirroring Amatrol training equipment, so that learners can perform the same tasks using virtual training systems that they would using Amatrol learning systems.

Benefits of Amatrol's virtual training systems include reducing initial program startup costs, requiring less classroom space, and offering integration with Amatrol's hardware systems if they are added in the future...

Amatrol's FaultPro, computer-based fault insertion system used on several troubleshooting simulators, allows for the insertion of faults to teach learners troubleshooting skills without the risk of damaging the equipment.

o automatic fault insertion, Amatrol incorporates many types of applications and load devices, both inertial and friction types, to help teach troubleshooting under realistic industrial conditions.

Extensive instrumentation is used to measure torque, speed, current, pressure, voltage, and flow, further enhancing the troubleshooting learning experience for students...

Read more

Amatrol offers unrivaled pairing of depth and breadth and hands-on skills in areas such as electrical, power, mechanical, electronics, and many more...

Amatrol's online iron and steel courses build job-ready competencies through theory and hands-on applications.

Amatrol's peerless multimedia curriculum utilizes text with voiceovers, pictures, videos, stunning 3D animations, and interactive quizzes and reviews that engage learners in knowledge and concepts to provide mining courses online.

Through partnerships with key industry leaders and leading educators, Amatrol developed the right balance of knowledge to train learners to work in their chosen field...

Amatrol's virtual simulators replicate hands-on equipment with realism and skill-building, mirroring Amatrol training equipment, so that learners can perform the same tasks using virtual training systems that they would using Amatrol learning systems.

Benefits of Amatrol's virtual training systems include reducing initial program startup costs, requiring less classroom space, and offering integration with Amatrol's hardware systems if they are added in the future...

Amatrol's FaultPro, computer-based fault insertion system used on several troubleshooting simulators, allows for the insertion of faults to teach learners troubleshooting skills without the risk of damaging the equipment.

o automatic fault insertion, Amatrol incorporates many types of applications and load devices, both inertial and friction types, to help teach troubleshooting under realistic industrial conditions.

Extensive instrumentation is used to measure torque, speed, current, pressure, voltage, and flow, further enhancing the troubleshooting learning experience for students...

Read more

Report

Related items: