hvac engineering precautions – it's better safe than sorry

Well, the source, whether it be fuel oil, natural gas, propane gas, refrigerant, or ammonia that generates the heating or cooling, each requires precautions when used as part of engineered system..

Carbon monoxide is odorless, colorless gas that results from burning oil, so it's important to make sure the room has ventilation maintained as equal or positive pressure within the room..

Maintaining positive pressure within the room is needed to assure combustion and reduce the risk of monoxide poison.

These safety relief valves must be vented to the outdoors to prevent the gas from being released into the room, where explosion can occur from spark or in the vicinity..

Solutions to fossil fuel and gas hazards include maintenance inspections, leak detection systems, pressure-relief piping to the outdoors, heat detectors, monoxide detectors, and preventing room from being under negative pressure.

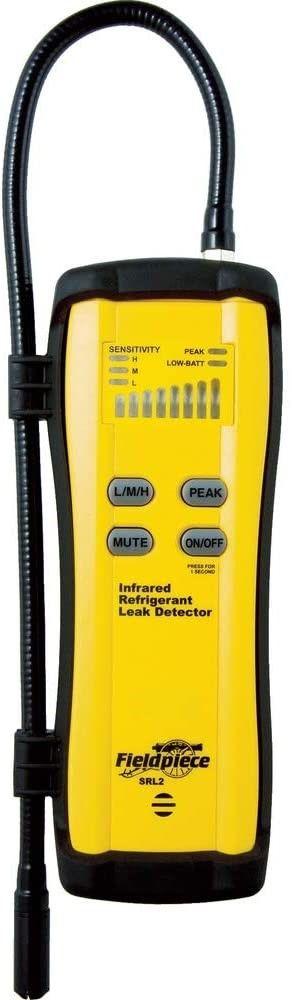

The major concern with the use of refrigerants is with equipment where hundreds of pounds of refrigerant are contained in unit.

these units have pressure relief valves that must be vented to the outdoors to protect any workers in the equipment room..

The solutions to these potential hazards are maintenance inspections, pressure-relief piping to the outdoors, refrigerant monitoring, and exhaust air system to the outdoors..

Ammonia refrigeration — This type of mechanical cooling is more in the sector of the business versus mechanical cooling in the commercial and institutional sectors.

o its performance to provide low-temperature cooling, it does not have greenhouse gas impact on the environment that chlorofluorocarbons and hydrochlorofluorocarbons have.

Read more

Carbon monoxide is odorless, colorless gas that results from burning oil, so it's important to make sure the room has ventilation maintained as equal or positive pressure within the room..

Maintaining positive pressure within the room is needed to assure combustion and reduce the risk of monoxide poison.

These safety relief valves must be vented to the outdoors to prevent the gas from being released into the room, where explosion can occur from spark or in the vicinity..

Solutions to fossil fuel and gas hazards include maintenance inspections, leak detection systems, pressure-relief piping to the outdoors, heat detectors, monoxide detectors, and preventing room from being under negative pressure.

The major concern with the use of refrigerants is with equipment where hundreds of pounds of refrigerant are contained in unit.

these units have pressure relief valves that must be vented to the outdoors to protect any workers in the equipment room..

The solutions to these potential hazards are maintenance inspections, pressure-relief piping to the outdoors, refrigerant monitoring, and exhaust air system to the outdoors..

Ammonia refrigeration — This type of mechanical cooling is more in the sector of the business versus mechanical cooling in the commercial and institutional sectors.

o its performance to provide low-temperature cooling, it does not have greenhouse gas impact on the environment that chlorofluorocarbons and hydrochlorofluorocarbons have.

Read more

Report

Related items: