hvac design considerations for pharmaceutical preparations

The hazard level and sterility requirements of compounded drug affect the cleanliness level, space pressurization, and air changes hour required in the room.

The room that hosts PEC is held to ISO Class environment and acts as area for PEC.

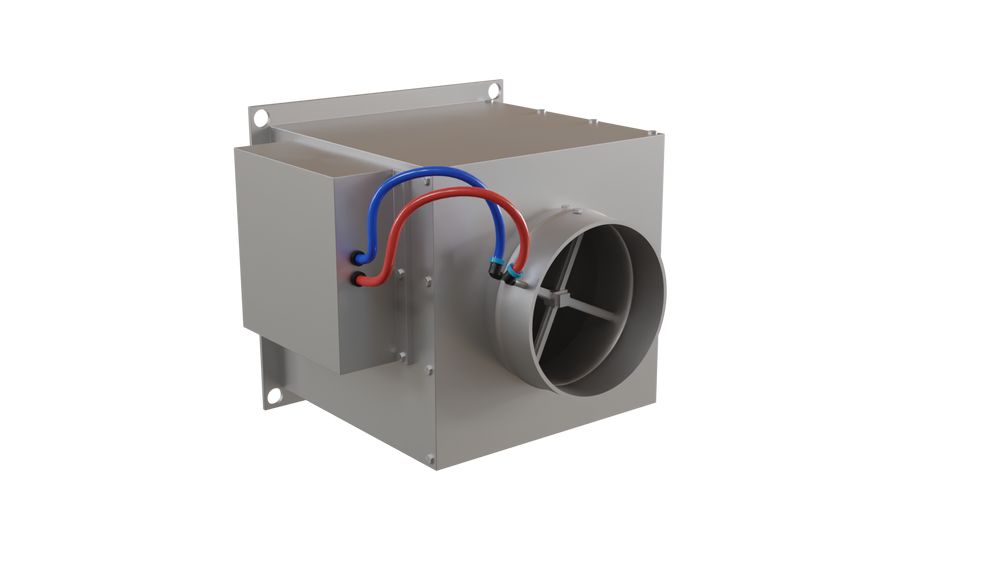

The air exiting PEC is considered suitable for the environment because it passes through bank of high-efficiency particulate air filters.

If the area and anteroom are separated, the pressure differential must be held to minimum of 0.02-0.05 inches column to minimize the spread of contaminants.

For both sterile and nonsterile HD preparations, C-SEC must be vented, negatively pressurized, and have pressure differential of 0.01-0.03 in wc relative to all adjacent areas that meet ISO classification level.

With understanding of the requirements that apply to different preparations, the conditions of the example space from Figure 1 start to become clear.

The anteroom that serves both NHD and HD compounding spaces must meet ISO Class 7 standards for air cleanliness, since it's bordering room for HDs.

In order to effectively monitor the pressurization requirements, USP 797 requires that pressure gauge or meter shall be installed to monitor the pressure differential or airflow between the area and ante-area and the ante-area and the environment outside the compounding area..

RH sensors located in the compounding rooms and anterooms monitor RH and inform the steam control valves to modulate order to maintain the minimum required 30% RH..

While air from NHD compounding rooms and pharmacy support spaces is allowed to be returned, it cannot be returned from HD compounding rooms.

Read more

The room that hosts PEC is held to ISO Class environment and acts as area for PEC.

The air exiting PEC is considered suitable for the environment because it passes through bank of high-efficiency particulate air filters.

If the area and anteroom are separated, the pressure differential must be held to minimum of 0.02-0.05 inches column to minimize the spread of contaminants.

For both sterile and nonsterile HD preparations, C-SEC must be vented, negatively pressurized, and have pressure differential of 0.01-0.03 in wc relative to all adjacent areas that meet ISO classification level.

With understanding of the requirements that apply to different preparations, the conditions of the example space from Figure 1 start to become clear.

The anteroom that serves both NHD and HD compounding spaces must meet ISO Class 7 standards for air cleanliness, since it's bordering room for HDs.

In order to effectively monitor the pressurization requirements, USP 797 requires that pressure gauge or meter shall be installed to monitor the pressure differential or airflow between the area and ante-area and the ante-area and the environment outside the compounding area..

RH sensors located in the compounding rooms and anterooms monitor RH and inform the steam control valves to modulate order to maintain the minimum required 30% RH..

While air from NHD compounding rooms and pharmacy support spaces is allowed to be returned, it cannot be returned from HD compounding rooms.

Read more

Report

Related items: