electronics manufacturing - dristeem

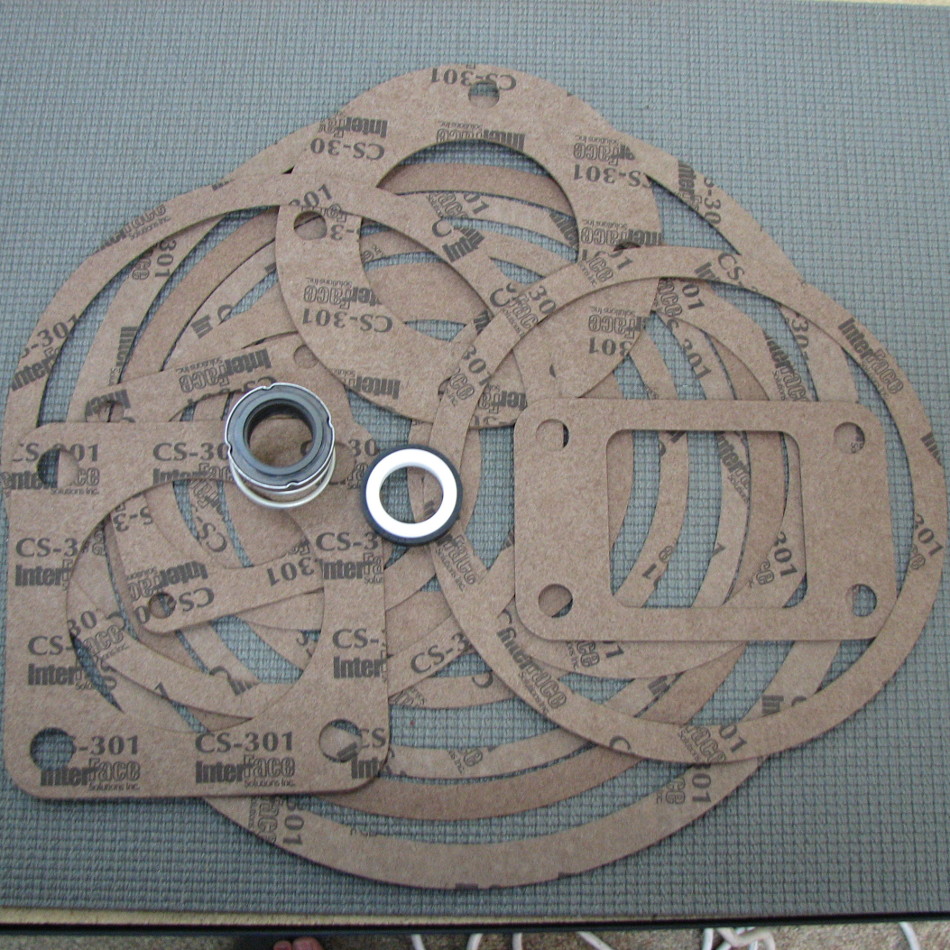

processes are increasing complexity —, multiple layers, delicate parts, and precise placements while operating margins shrinking.

Maintaining the appropriate humidity level within the facility helps to decrease damage and stress to electronic components, helping to protect your reputation as leader and improve ROI. .

In brittle components, reduced ineffective soldering, and de-soldering occurrences, as well environment for staff.

The use of humidity can be an additional layer of ESD Protected Area helping absorb and more distribute excess charges, minimizing electricity, and protecting staff. While the build-up of electrostatic charge increases at humidity, humidity levels pose issues as well.

humidity levels between 30 and 70 percent is recommended. .

The addition of humidity to the air within manufacturer facilities reduces electrostatic discharges, product defects, and downtime. Integrating humidification system into HVAC system is an economical and way for electronic manufacturers to provide protection to products and staff. .

In environment with too little humidity the potential of electrostatic discharge increases which can damage product and harm staff..

High humidity creates environment while environment is created within humidity which increases static electricity. .

By controlling the humidity within facility, electronic manufacturers can reduce the airborne transmission of viruses like SARS-CoV-2 and the seasonal flu. ..

By low or fluctuating humidity levels can affect, Learn more how issues caused an electronics manufacturing facility, creating the potential for inaccurate results and reducing life span of expensive equipment. ...

Read more

Maintaining the appropriate humidity level within the facility helps to decrease damage and stress to electronic components, helping to protect your reputation as leader and improve ROI. .

In brittle components, reduced ineffective soldering, and de-soldering occurrences, as well environment for staff.

The use of humidity can be an additional layer of ESD Protected Area helping absorb and more distribute excess charges, minimizing electricity, and protecting staff. While the build-up of electrostatic charge increases at humidity, humidity levels pose issues as well.

humidity levels between 30 and 70 percent is recommended. .

The addition of humidity to the air within manufacturer facilities reduces electrostatic discharges, product defects, and downtime. Integrating humidification system into HVAC system is an economical and way for electronic manufacturers to provide protection to products and staff. .

In environment with too little humidity the potential of electrostatic discharge increases which can damage product and harm staff..

High humidity creates environment while environment is created within humidity which increases static electricity. .

By controlling the humidity within facility, electronic manufacturers can reduce the airborne transmission of viruses like SARS-CoV-2 and the seasonal flu. ..

By low or fluctuating humidity levels can affect, Learn more how issues caused an electronics manufacturing facility, creating the potential for inaccurate results and reducing life span of expensive equipment. ...

Read more

Report

Related items: