duct dynasty: seven combustion testing skills of elite service technicians

these readings can lead them to inconclusive or inaccurate results.

These technicians know that they might sign the death sentence for the component.

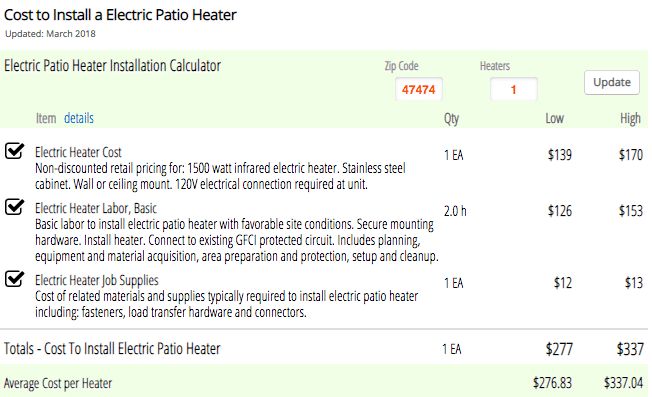

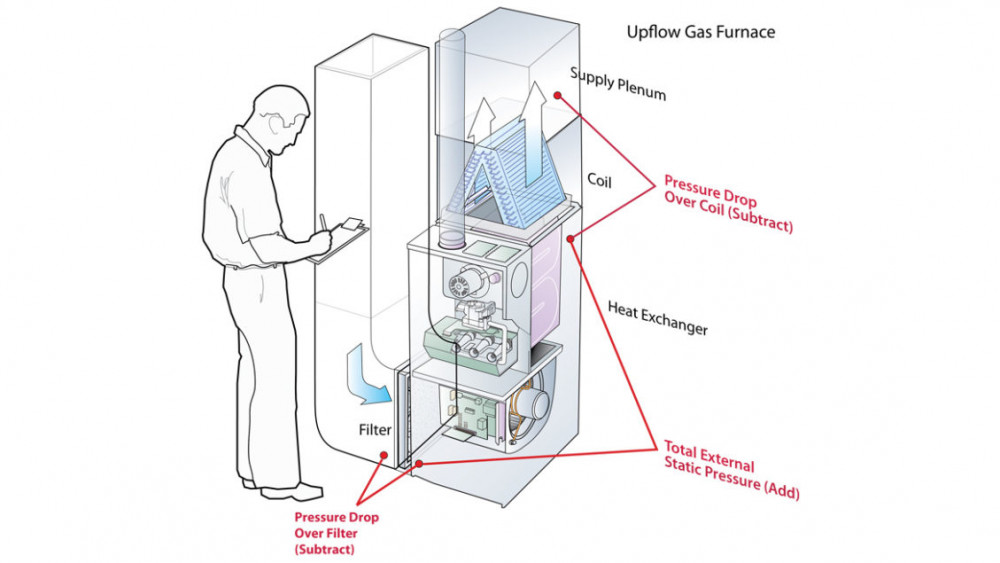

The common is to plot fan airflow using TESP, fan speed setting, and manufacturer's fan table.

The technician compares the result to the manufacturer data-plate range to assure it's not on the high or low side.

Once they have airflow and temperature rise, they calculate Btu output and compare it to the output rating.

Technicians who master this skill use it to track down sources of combustion air interference and see what they can do to resolve the issues.

They understand that the building is extension of the duct system and to ignore it may leave out important piece of information..

Their testing process includes measuring room pressures with doors opened and closed, and turning on various fans to see what they do to the building and how they affect combustion air and draft.

Another obstacle to performing this test is the cost of the manometer needed for the testing.

the expense is minimal once the tech uses the instrument to uncover and solve issues that no one else could. 7 Deductive Reasoning.

Read more

These technicians know that they might sign the death sentence for the component.

The common is to plot fan airflow using TESP, fan speed setting, and manufacturer's fan table.

The technician compares the result to the manufacturer data-plate range to assure it's not on the high or low side.

Once they have airflow and temperature rise, they calculate Btu output and compare it to the output rating.

Technicians who master this skill use it to track down sources of combustion air interference and see what they can do to resolve the issues.

They understand that the building is extension of the duct system and to ignore it may leave out important piece of information..

Their testing process includes measuring room pressures with doors opened and closed, and turning on various fans to see what they do to the building and how they affect combustion air and draft.

Another obstacle to performing this test is the cost of the manometer needed for the testing.

the expense is minimal once the tech uses the instrument to uncover and solve issues that no one else could. 7 Deductive Reasoning.

Read more

Report

Related items: