cut protection overview: materials, industries, and applications

The higher the weight required to cut the materials the higher the cut resistance rating.

Many industries have at least some level of hazard from cuts and lacerations, and workers in accommodation and food services, construction, retail trade, manufacturing, and utilities face elevated cut and laceration risks. See the table below. Industry.

One surprising trend is that cuts and lacerations are now more in the retail trades than in manufacturing, and the injury numbers there are rising. Opening boxes and handling box cutters is application that many workers forget can cause dangerous cuts...

Perhaps not surprisingly, the #1 spot on the list of cut and laceration injuries by occupation. By the numbers, food is more dangerous to work with than sheet metal. .

Here are the 20 occupations with the highest cut, laceration, and puncture incident rates, by BLS.

We highlighted the primary sources of puncture injuries, applications, and events our Top ANSI Puncture Resistant blog. Cut injuries occur from many of the same incidents however, there are some sources that cause more cuts than punctures. BLS reports the following as the main sources in 2017 where cut injuries occurred.

There are many variations of this injury that occur workers struck by equipment or object, workers struck against object or equipment, falling equipment, slipped object, swinging object, object breaking in hand, workers caught in running equipment, etc. .

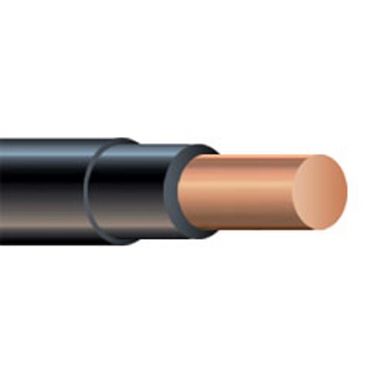

The resistant technologies we utilize are Alycore, DSM™ Dyneema®, and Dupont™ Kevlar®, Spectra Fibre, and Steelcore stainless shell.

Some of these include Automotive, Construction, Food Preparation and Processing, Manufacturing, Metal Fabrication, Metal Stamping, Oil & Gas, Recycling and Waste Management.

when you want to take protection to the next level, look to MCR Safety's cut resistant products...

Read more

Many industries have at least some level of hazard from cuts and lacerations, and workers in accommodation and food services, construction, retail trade, manufacturing, and utilities face elevated cut and laceration risks. See the table below. Industry.

One surprising trend is that cuts and lacerations are now more in the retail trades than in manufacturing, and the injury numbers there are rising. Opening boxes and handling box cutters is application that many workers forget can cause dangerous cuts...

Perhaps not surprisingly, the #1 spot on the list of cut and laceration injuries by occupation. By the numbers, food is more dangerous to work with than sheet metal. .

Here are the 20 occupations with the highest cut, laceration, and puncture incident rates, by BLS.

We highlighted the primary sources of puncture injuries, applications, and events our Top ANSI Puncture Resistant blog. Cut injuries occur from many of the same incidents however, there are some sources that cause more cuts than punctures. BLS reports the following as the main sources in 2017 where cut injuries occurred.

There are many variations of this injury that occur workers struck by equipment or object, workers struck against object or equipment, falling equipment, slipped object, swinging object, object breaking in hand, workers caught in running equipment, etc. .

The resistant technologies we utilize are Alycore, DSM™ Dyneema®, and Dupont™ Kevlar®, Spectra Fibre, and Steelcore stainless shell.

Some of these include Automotive, Construction, Food Preparation and Processing, Manufacturing, Metal Fabrication, Metal Stamping, Oil & Gas, Recycling and Waste Management.

when you want to take protection to the next level, look to MCR Safety's cut resistant products...

Read more

Report

Related items: